Works on the ETYFA Flagship project which will supply clean natural gas to Vassilikos Power Station continue unabated in spite of the terrible global situation as a result of the Covid 19 Pandemic.

Two vital components that have to be installed on the Liquified Natural Gas (LNG) carrier, ETYFA PROMETHEAS, are the Regassification (Regas) Module and the Power Module.

The Regas Module is responsible for converting the Liquid Natural Gas to a Gaseous Natural Gas state (Natgas) and deliver this gas to the Vassilikos Power Station in order to power the combined cycle turbines which generate electricity for The Republic of Cyprus. The Regas module is being installed on the bow of the ship.

In order to further reduce the carbon footprint in the Republic of Cyprus the contractor, China Petroleum Pipeline Company (CPP), is installing a dual fuel Power Module to drive the Regas module as well as power the rest of this marine giant insofar as electricity and associated power derivatives are concerned. The Power module will run exclusively on LNG from the cargo onboard the vessel but has the ability to switch to diesel should the need arise in an emergency. The Power Module is being installed on the stern of the ship.

Once these two critical items have been installed the vessel then truly becomes a Floating, Storage and Regassification Unit (FSRU) as well retaining the full functions of a tradeable LNG commercial carrier.

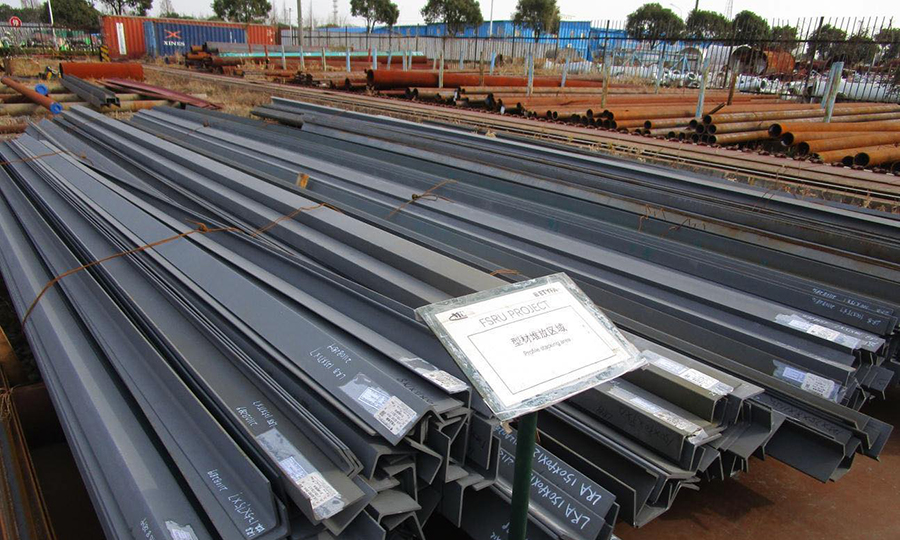

CPP, as a prudent and very experienced contractor, has secured the necessary steel for the fabrication of these two modules despite the massive supply bottlenecks and record high prices that the global pandemic has created. This has assisted in minimising although not completely avoiding delays that most contractors in the marine field are experiencing due to the pandemic. ETYFA representatives attended the steel cutting ceremony for the Regas Module on 28 October 2021. Fabrication of the Regas Module commenced immediately thereafter at the giant COSCO shipyard in China. The steel cutting for the Power Module was done on 09 December 2021 with fabrication, again, commencing immediately thereafter.

The fabrication process of these two modules has continued on an uninterrupted basis throughout the holiday period. CPP made various detailed and robust plans to manage travel restrictions, area closures and other pandemic related disruptions which have been successfully implemented and have thus far resulted in no lost work days. A considerable achievement under the current pandemic circumstances.

Fabrication of the bases/blocks for both the Regas and Power Modules are already 52% completed. CPP and COSCO remain focused on meeting quality, safety and time objects.

CPP has reconfirmed that they are fully committed to delivering a world class facility to the Republic of Cyprus and have repeated their thanks to the people of Cyprus for their continued support in this endeavour.